What Does a Mansard Roof Look Like? A Stylish Staple in West Palm Beach, Florida Architecture

From the sun-drenched streets of West Palm Beach, Florida, where coastal charm meets upscale elegance, homeowners are increasingly asking: “What does a mansard roof look like?” And more importantly—why is it becoming a sought-after architectural feature in South Florida’s design scene?

If you’ve driven past historic estates on Flagler Drive or eyed new luxury builds near El Cid or SoSo, chances are, you’ve glimpsed the stately silhouette of a mansard roof. With its sophisticated lines and heritage flair, this roofing style isn’t just aesthetically pleasing—it’s a symbol of timeless design. With David Spade of Star Roofing, let’s unpack what really makes a mansard roof unique, why it’s gaining popularity in Palm Beach County, and how it blends form and function for the modern homeowner.

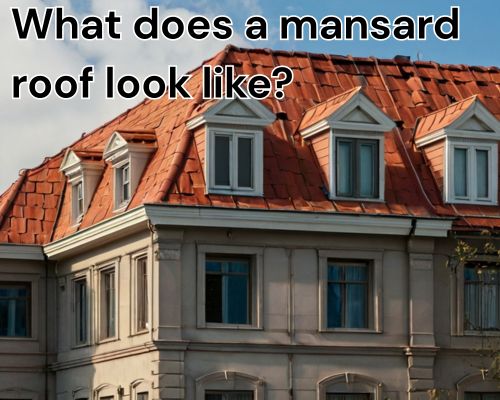

So, What Does a Mansard Roof Look Like?

A mansard roof, also known as a French roof, features a distinctive double-slope design on all four sides. The lower slope is typically steep, sometimes nearly vertical, while the upper slope is much shallower. This creates a boxy profile that maximizes attic space, often transforming it into fully usable living quarters—referred to as a mansard loft or garret.

Visually, a mansard roof is like a top-hat for your home—elegant, structured, and distinctly Parisian in flavor. It often includes dormer windows, copper flashing, ornate brackets, and even decorative shingles, all contributing to a high-end curb appeal that screams architectural pedigree.

A Bit of History: From Paris to Palm Beach

The term “mansard” hails from François Mansart, a 17th-century French architect who popularized this style during the Baroque period. Fast-forward to the Second Empire architectural era, and the mansard roof became a cornerstone of stylish urban dwellings in both Europe and America.

In West Palm Beach, mansard roofs were once limited to historic revival homes and mid-century estates, but they’ve now made a strong comeback in custom new construction, thanks to their blend of space efficiency and classic design.

Why It Works in West Palm Beach, Florida

You might wonder how a roofing style born in the cool climates of Europe fits into West Palm Beach’s tropical environment. The answer lies in its adaptability and form.

1. Extra Living Space

Real estate in West Palm Beach is premium—especially in neighborhoods like Northwood Shores, Southland Park, and Prospect Park. The mansard roof allows for full additional stories without altering a home’s footprint. Perfect for guest suites, home offices, or studio apartments.

2. Aesthetic Versatility

Whether it’s Mediterranean Revival, Art Deco, or Contemporary Coastal, the mansard roof can be customized to complement various architectural styles prevalent in the Palm Beaches.

3. Durability Under the Sun

Today’s mansard roofs are constructed with high-performance asphalt shingles, metal panels, or even synthetic slate—materials designed to withstand UV rays, salt air, and heavy rainfall, which are common in this humid subtropical climate.

Salient Architectural Entities and LSI Touchpoints

To truly understand what a mansard roof looks like, it helps to compare it with other popular styles in West Palm Beach:

- Gable Roof: Features a triangular shape with two sloped sides. Less attic space, but great for drainage.

- Hip Roof: Slopes on all four sides, meeting at a ridge. Offers stability in high-wind zones like coastal Florida.

- Flat Roof: Common in modern and commercial builds. Minimalist aesthetic but limited in attic use.

The mansard roof stands out because it cleverly combines the full-volume attic potential of a gable with the four-sided wind resistance of a hip roof.

📍 Notable LSI keywords related to this style include:

“roof dormers,” “French-inspired home design,” “elegant roofline,” “West Palm Beach mansions,” “custom home roofs in Florida,” “historic Florida architecture,” and “energy-efficient attic solutions.”

Who’s Choosing Mansard Roofs in West Palm Beach?

Luxury homebuilders, boutique developers, and even restoration specialists are embracing the mansard roof trend. If you’re checking out projects by The Courchene Development Corporation or updates to homes in Old Northwood Historic District, expect to see this profile gracing facades both old and new.

Realtors in West Palm Beach, like those at Douglas Elliman or Brown Harris Stevens, often highlight mansard roofs as a high-value architectural feature, especially when listing historic or remodeled properties near the Intracoastal Waterway.

Customization Trends & Design Upgrades

In 2025, modern mansard roofs are shedding their purely historic skin and entering the realm of innovation:

- Skylights are being integrated to enhance natural light in the upper story.

- Solar panels are now hidden within the upper shallow slope, allowing for eco-conscious living without disrupting the aesthetics.

- Green roofs are being layered onto mansard tops for insulation and sustainability.

Interior designers are also transforming these formerly cramped top floors into spa-like primary suites, home theaters, and even indoor-outdoor lounges with French balconies. See Star Roofing for more.

Final Thoughts: Mansard Roofs and the Palm Beach Prestige Factor

So, what does a mansard roof look like? In West Palm Beach, it looks like luxury, legacy, and livable elegance—crafted into a shape that’s as practical as it is picturesque.

Whether you’re walking along the Norton Museum of Art, visiting friends in South End, or gazing at the skyline near CityPlace, keep your eyes lifted. Those dramatic upper floors with their distinctive slant and elegant dormers? That’s a mansard roof—reminding us that timeless design never goes out of style, especially not in one of Florida’s most architecturally expressive cities.

Call to Action

Thinking about incorporating a mansard roof into your next remodel or custom home in West Palm Beach? Work with local architects familiar with both the technical and stylistic nuances. Not only will you add elegance and functionality—you’ll raise your property’s value and turn heads for all the right reasons.